Sheet metal design

Introduction to Sheet Metal Design

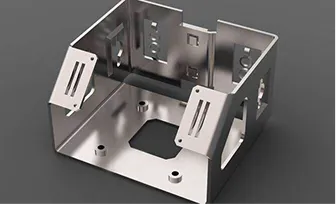

Sheet metal design involves creating components and assemblies from thin, flat metal sheets. It is widely used in industries such as automotive, aerospace, electronics, and machinery. The process requires knowledge of metal properties, design standards, and manufacturing techniques to ensure strength, durability, and cost-effectiveness.

Key Design Considerations

When designing sheet metal parts, factors like bend radius, material thickness, hole size, and relief cuts are critical. These considerations ensure manufacturability and minimize defects. Accurate flat patterns are generated to account for bend allowances and avoid issues during fabrication.

Common Sheet Metal Operations

Common operations include cutting, bending, punching, embossing, and welding. Each operation affects material behavior and design strategy. Software like SolidWorks and Inventor includes tools to simulate and validate these operations before production, reducing errors and waste.

Applications of Sheet Metal Design

Sheet metal is used in enclosures, brackets, chassis, ductwork, and structural components. Its versatility, light weight, and durability make it ideal for mass production. Design optimization helps meet functional requirements while keeping material and manufacturing costs low.