Rapid Prototyping and 3D Printing

Introduction to Rapid Prototyping and 3D Printing

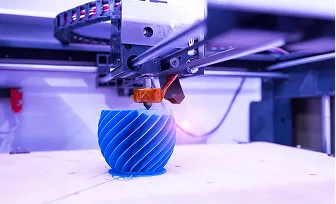

Rapid prototyping and 3D printing are cutting-edge technologies used to quickly create physical models of a product or component. They play a critical role in reducing the time and cost associated with traditional prototyping methods. By using a digital design, 3D printers can fabricate physical models layer by layer, allowing for fast iterations and testing of design concepts before moving to full-scale production.

Rapid Prototyping Process

The rapid prototyping process begins with creating a 3D digital model of the product, which is then fed into a 3D printer. The printer uses additive manufacturing techniques to build up the model layer by layer, using materials like plastic, metal, or resin. This approach allows for quick production of prototypes that can be tested for form, fit, and function before making expensive tooling for mass production.

Benefits of Rapid Prototyping and 3D Printing

One of the key benefits of rapid prototyping and 3D printing is the ability to quickly turn an idea into a physical object, allowing for fast feedback and iteration. It reduces lead times and costs associated with traditional prototyping methods. Additionally, it enables the production of complex geometries that would be difficult or impossible to achieve with conventional manufacturing techniques. The ability to test prototypes in real-world conditions can help in refining the design before production.

Applications of Rapid Prototyping and 3D Printing

Rapid prototyping and 3D printing are widely used in various industries including automotive, aerospace, healthcare, and consumer products. In automotive and aerospace, these technologies are used for creating functional prototypes of parts and components. In healthcare, they enable the production of patient-specific medical devices or models for surgical planning. In consumer products, rapid prototyping allows for faster design iterations and better consumer testing before final production.

Materials Used in 3D Printing

3D printing uses a variety of materials depending on the intended application. Common materials include PLA, ABS, nylon, and resins for plastic prototypes, as well as metals like aluminum and stainless steel for more robust parts. These materials are selected based on factors such as strength, flexibility, and heat resistance, which are critical to the final product's functionality and performance.

Types of 3D Printing Technologies

There are several different 3D printing technologies, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). FDM is commonly used for creating prototypes with thermoplastic materials. SLA uses lasers to cure liquid resin into solid shapes, making it ideal for highly detailed prints. SLS uses lasers to fuse powdered materials, allowing for the production of durable and complex parts, often used in industrial applications.

Advantages of 3D Printing Over Traditional Methods

Compared to traditional manufacturing techniques, 3D printing offers several advantages. It eliminates the need for expensive molds or tooling, reduces material waste, and allows for the creation of complex geometries. Additionally, 3D printing offers high customization, enabling the production of small batches or even one-off prototypes tailored to specific requirements. This flexibility makes it ideal for both prototyping and low-volume production runs.

Challenges of 3D Printing

While 3D printing offers many benefits, it also comes with challenges. The speed of production can sometimes be slower than traditional manufacturing methods, particularly for large or complex parts. The surface finish of 3D printed parts may not always meet the standards required for certain applications, which could require additional post-processing. Furthermore, the selection of materials and the need for specialized equipment can limit the types of products that can be created with 3D printing.

The Future of Rapid Prototyping and 3D Printing

The future of rapid prototyping and 3D printing looks promising, with ongoing advancements in materials, printing speeds, and capabilities. As these technologies evolve, they will become even more integrated into the manufacturing process, enabling faster and more efficient production. In particular, advancements in 3D printing for metal parts and the development of multi-material printing are expected to unlock new possibilities for industries ranging from aerospace to healthcare.