Parametric conversion of CAD from one software to another

Introduction to Parametric CAD Conversion

Parametric CAD conversion refers to the process of transferring CAD models between different software environments while maintaining the parametric design features, such as dimensions and constraints. This ensures that the design remains editable and can be adjusted in the new software without losing its original parameters.

Software Compatibility

Parametric CAD conversion is essential when moving designs between different platforms like SolidWorks, AutoCAD, CATIA, and Inventor. Each software has its own way of managing parametric constraints and design features, and ensuring compatibility is key. This process guarantees that the final model works seamlessly in the new environment.

Conversion Process

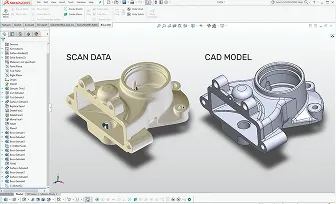

The process includes importing the original CAD model, identifying parametric features, and mapping them to the corresponding features in the target software. Special attention is given to maintaining constraints, dimensions, and relationships between parts. After conversion, we validate the model to ensure the parametric behavior is preserved.

Benefits of Parametric Conversion

Parametric conversion allows for smoother collaboration between teams using different CAD software. It also provides flexibility in choosing the most appropriate platform for different stages of product development. The ability to maintain parametric relationships reduces the risk of errors and speeds up the design iteration process.

Challenges & Solutions

One challenge in parametric CAD conversion is the loss of features specific to certain software. Some software might not support certain types of parametric relationships. To overcome this, we utilize advanced tools and techniques to either recreate or adapt those features to the target platform without compromising the model's integrity.

Output and Final Model

The final output is a fully parametric CAD model that can be used for further design, analysis, and manufacturing in the new software. This model retains all parametric relationships, dimensions, and features, ensuring that it is ready for any modifications or adjustments needed down the line.

Quality Control & Validation

After conversion, we conduct extensive checks to ensure that the parametric relationships are intact and functional. This includes testing the model for dimension changes, feature movement, and constraint behaviors. Validation ensures that the converted model meets the required standards and is fully functional in the target software.