Sheet metal design

Introduction to FEA/CFD Analysis

FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) are simulation techniques used to predict the behavior of structures and fluids. These tools help engineers identify stress points, heat flow, and fluid dynamics to enhance performance and safety.

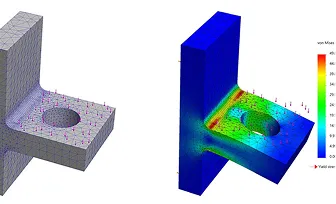

Finite Element Analysis (FEA)

FEA breaks down complex geometries into smaller elements for stress, strain, and thermal simulations. It's widely used in structural design, product validation, and failure prediction. This reduces the need for physical testing and shortens development cycles.

Computational Fluid Dynamics (CFD)

CFD simulates fluid flow, heat transfer, and aerodynamics. It’s applied in automotive, aerospace, and HVAC industries to optimize efficiency and design. CFD helps visualize airflow patterns and identify performance issues before prototype development.

Applications and Benefits

FEA/CFD are essential in design optimization, cost reduction, and improving product reliability. These tools are used in R&D, quality assurance, and troubleshooting to ensure products meet safety and performance standards before manufacturing.