CAD creation based on measurements / photos

Introduction to CAD Creation Based on Measurements / Photos

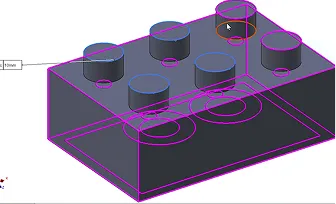

CAD creation based on measurements or photos involves converting physical objects or their visual representations into precise digital models. This technique is useful when original CAD files are unavailable or when objects need to be replicated or modified. Using tools like 3D scanning, photography, and measurement software, designers can accurately recreate an object in CAD for further analysis, prototyping, or manufacturing.

Process of CAD Creation

The process begins with taking precise measurements of the object, either through direct measurement tools (like calipers or laser scanners) or by capturing photos from multiple angles. These measurements or images are then input into CAD software such as AutoCAD, SolidWorks, or Fusion 360 to create a 3D model. The CAD model is refined by applying accurate dimensions, geometry, and design features for a detailed and functional model.

Applications of CAD Creation Based on Measurements / Photos

This method is widely used in industries where precise replication or modification of existing objects is required. It’s often applied in fields like manufacturing, automotive, product design, and architecture. For example, creating replacement parts for machinery, redesigning an object for improved functionality, or creating custom products based on client specifications can all be accomplished through CAD creation based on measurements and photos.

Tools for CAD Creation Based on Measurements / Photos

Various tools are used in this process, including traditional measuring instruments like rulers, calipers, and micrometers, as well as advanced equipment such as 3D scanners and photogrammetry software. 3D scanning allows for the quick capture of an object's geometry, while photogrammetry involves using photographs taken from different angles to create a 3D model. CAD software such as AutoCAD, Rhino, and SolidWorks is then used to refine and modify these models for further use.

Benefits of CAD Creation

The primary benefit of CAD creation from measurements and photos is the ability to recreate an object accurately when no original CAD data is available. This method also ensures that custom designs are built to precise specifications, improving the accuracy and functionality of the final product. Additionally, the digital model can easily be edited, optimized, and tested for functionality, allowing for better planning and prototyping.

Challenges in CAD Creation Based on Measurements / Photos

One of the challenges is ensuring the accuracy of measurements and translating them into precise CAD models. Inaccurate measurements or photo distortions can lead to errors in the final CAD model, impacting design or functionality. Additionally, objects with complex geometries may require more advanced techniques like 3D scanning to capture all details accurately. Depending on the object, this process may also be time-consuming and require significant expertise in both measurement and CAD modeling.

CAD Creation for Custom Designs

When designing custom products, CAD creation from measurements and photos allows for the perfect fit and functional design based on the user's specific needs. Whether it’s a custom part for machinery or a unique product design, this approach ensures that the final product is accurate and tailored to specifications. It also facilitates the process of iterative design, where changes can be quickly made to the CAD model to explore different design options.

Conclusion

CAD creation based on measurements and photos is a vital technique for industries requiring precise design and replication. It enables accurate modeling of objects, even when no original CAD files exist. By leveraging measurement tools, scanning technologies, and advanced CAD software, businesses can create high-quality models for a variety of applications, from prototyping to manufacturing, and ensure the final product meets exact specifications.